Welcome to ArcRev's Precision Surface Texturing Services

Unlock the potential of your medical devices with ArcRev’s cutting-edge laser surface texturing services. Our commitment to excellence ensures greater patient safety, enhanced functionality, and extended longevity for your devices. With a focus on R&D development, we offer expedited 24-72 hour lead times for small volume orders.

Understanding Medical Device Surface Texturing

Medical device surface texturing is a vital process at the core of patient safety, comfort, and optimized drug delivery. It entails meticulous manipulation of implant and medical device surfaces through chemical or mechanical methods to impart specific physical properties essential for their intended use. This section explores various surface texturing techniques available at ArcRev and their wide-ranging applications.

What is Medical Device Surface Texturing?

At ArcRev, we employ advanced laser technology to modify the surfaces of medical devices, such as implants and needles, granting them tailored physical properties. Our laser surface texturing process yields devices with heightened patient safety, enhanced comfort, improved functionality, advanced drug delivery systems, and extended longevity.

The Purpose of Surface Texturing

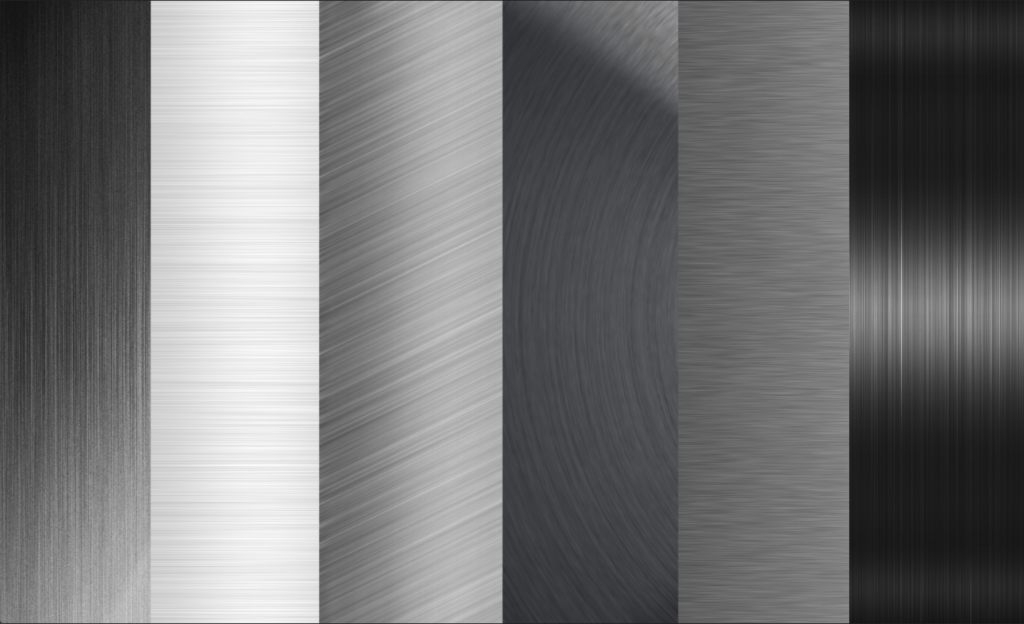

Medical device surface texturing primarily aims to augment the surface area of devices, enhancing their physical properties. From subtle dimples and scratches to microstructures reminiscent of a razor blade, these modifications make devices more resilient to friction and wear. The outcomes include improved biocompatibility, reduced infection risk, and enhanced fluid flow over the device surface.

Precision with Laser Technology

Our state-of-the-art laser technology ensures precision in crafting intricate patterns with uniform depth on any medical device surface. This process eliminates burrs and imperfections, allowing for meticulous control over the degree of etching. Laser texturing creates indentations that enhance overall device grip and tactile response. Additionally, it significantly reduces bacterial growth, simplifying the cleaning and maintenance process. Our team excels in producing custom-etched textures with a variety of waveform shapes and depths, providing increased gripping power for medical instrumentation.