Discover the Future of Medical Device Fabrication with Flat Sheet Laser Cutting!

Experience a groundbreaking transformation in medical device manufacturing through the precision and efficiency of Medical Device Flat Sheet Laser Cutting. This cutting-edge technology holds the promise of enhancing patient outcomes, minimizing manufacturing expenses, and ensuring the safety of products. Learn more about the revolutionary Medical Device Flat Sheet Laser Cutting process here!

What is Flat Sheet Laser Cutting?

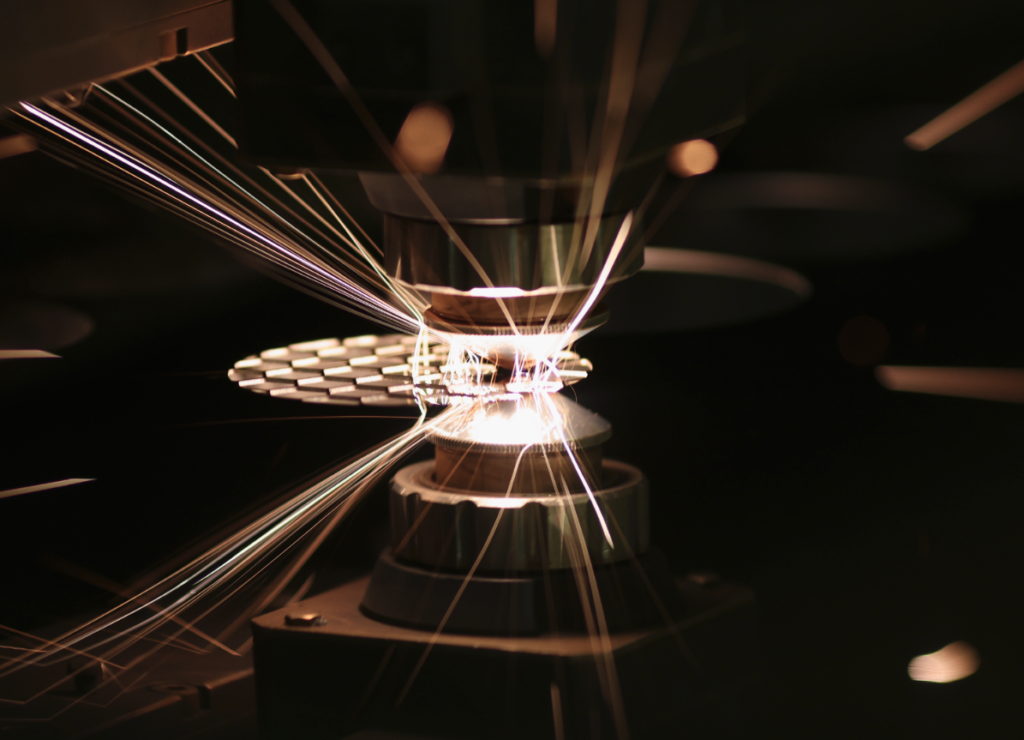

Medical Device Flat Sheet Laser Cutting represents a sophisticated and incredibly precise manufacturing technique that utilizes a focused beam of light energy to accurately cut through flat sheets of various materials, including metal and plastic. The CNC machine generates the laser beam, which can be programmed to cut into any size and shape with unparalleled precision. This capability enables the production of intricate components with exacting accuracy, even when dealing with challenging curves or complex shapes.

Versatility in Material Application

Medical Device Flat Sheet Laser Cutting is versatile and capable of cutting through a diverse range of materials, each with varying thickness levels. Commonly processed materials include aluminum, stainless steel, cobalt chrome, and titanium in sheet or coil form. Furthermore, the technology is adept at handling plastic and various composite materials. Its exceptional precision makes it ideal for crafting intricate components like gaskets used in medical device manufacturing.